WOODEN PASSIVE HOUSES: DESIGN PRINCIPLES AND TECHNICAL DETAILS

- Daniel Butucel

- Jul 28, 2021

- 4 min read

What are the criteria for a passive house and what advantages does the wood bring to a passive house?

What is a passive house?

Lately, we have been more and more confronted with the concept of passive house, however not many understand what a passive house or the Passivhaus standard means. Passivhaus Institut from Darmstadt, Germany, has created the Passivhaus standard aiming to reduce buildings’ power consumption, thus their impact on the environment.

This standard is extremely strict and aims for the maximum optimizing of the therma requirement of a building, through simple, yet rigorous methods and techniques. It applies not only to houses, but also to public or commercial buildings and the first certified hospital following this system will soon be added to the list.

In order for a house to be passive, it needs to meet a very important criterion (among others), namely the annual energy consumption cannot surpass 15kWh/ square meter/ year or maximum thermal load should be lower than 10 W/ square meter. As an order of magnitude, the conventional flats have an annual power consumption of 100-150 kWh/ square meter/ year and the ones built before ’89 reach up to 300 kWh/ square meter/ year.

Therefore, a passive house is not energy independent, but it has a very low thermal requirement, which can be easily covered by a heat source, at very low costs. There are some houses whose thermal requirement is so low, that it is covered by heat from its inhabitants.

The principles of a passive house

In order to reach the 15 kWh/ square meter/ year target, Passivhaus Institut has elaborated a practical guide based on 5 simple principles:

They are:

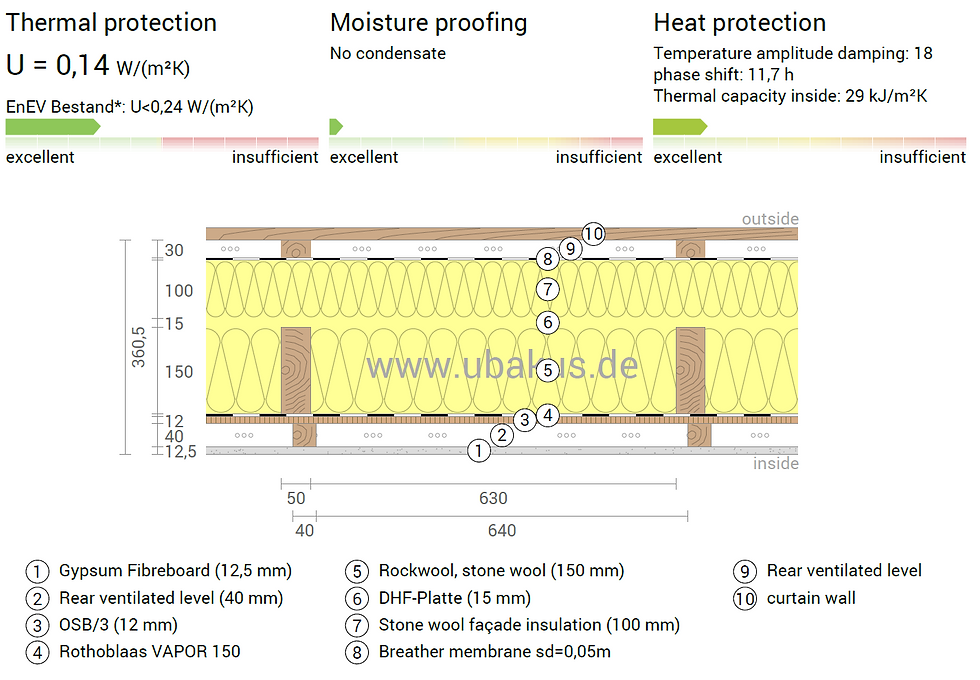

Sufficient thermal insulation: the opaque thermal envelope of the building ( the external walls and the roof) has to have the lowest possible heat transfer coefficient U<0,15 W/m2K (R=6,67 m2K/W), that can be achieved through thermal insulation of external walls with an adequate insulating layer, resulted from calculi.

Energy efficient windows: the collection made of the carpentry frame (PVC, wood, aluminium) and triple low-e glass needs to have the coefficient U<0,80 W/m2K (R=1,25 m2K/W).

Air tightness: uncontrolled air infiltrations are a big problem for a building, especially for a wooden one, because the infiltrated air causes heat loss and the humidity can condense inside the structure and in time, it causes significant damage. That is why, the number or hourly exchanges should not exceed 0,6 of the house’s total volume.

Heat recovery ventilation: in order to ensure a constant intake of fresh air, without power loss, a passive house needs to be equipped with a mechanical heat recovery ventilation system that has a thermal transfer efficiency of over 75%.

Breakage of thermal decks: each corner, jointing between structural elements, boards or thermal envelope configuration need to be treated carefully in order to minimize thermal decks, namely those areas where there is uncontrolled heat transfer with the environment.

At the first glance, these are simple principles, but within a project they become rigorous and need interdisciplinary collaboration between the architect, the engineer and the construction worker.

Almost any building can be passive if the certification project starts from the prototype stage. Also, a passive house can be built in any structural system, whether wood, brickwork, light steel structure ICF, SIP panels. We focus on wood, namely on the timberframe system.

Wooden passive houses

Wood as a building material has an advantage compared to other structural materials concerning the thermal reaction. Wood’s thermal conductivity (how much heat is transferred through it), coefficient λ = 0,14 W/MK, much lower than steel (λ = 50 W/MK), concrete (λ = 2 W/MK) or brick (λ = 0,25 W/MK). On the other hand, thermo-insulating materials such as mineral wool, polystyrene, cellulose, straw and similar ones have a λ = 0,032-0,04 W/MK.

Within the timberframe structural system, which I have talked about extensively in this article, the wooden frame bearing leaves room inside for the thermal insulation, so a wall does not contain only a wooden structure, but also thermal insulation and in this collection, it comes closer to the passive house’s thermal insulation criterion in a relatively reduced wall thickness. With an external thermal system, the wall coefficient U drops below 0,15 W/m2K and thus the thermal bridges in the wooden pillar are also limited.

Another advantage of the timberframe houses is the logistical one. The walls are manufactured in factories, on different lengths that can reach up to 10 m and they are assembled by crane on the construction site, therefore significantly reducing the production lead time and the associated costs.

Why passive houses?

Because starting from next year, new residential buildings that do not meet the nZEB (nearly Zero Energy Building) standard- namely construction works that have a power consumption of almost 0 and a energy intake coming from renewable sources of at least 10%) will no longer receive a building permit- according to Directive 2010/31/UE of The European Parliament and The European Union Council regarding buildings’ energy performance. As there are no clear regulations yet in Romania, in order to achieve the nZEB standard, a building needs to have a very low power consumption, just like a passive house.

Or how we like to say, the road to nZEB passes through Passivhaus.

Comments