WHY BUILD WITH WOOD?

- Daniel Butucel

- Jan 13, 2022

- 7 min read

5 reasons why wood is an exceptional building material

In this article, we are talking about wood, probably the most misunderstood building material, which is surrounded not only by unfounded opinions but also by myths transmitted from one generation to another through inexperienced people on site. Even though most Romanians stay away from wooden houses because wood is a combustible material, however, most roofs and attics are made of wood.

Not so long ago, in our country, wood was thought to be an inferior building material, mostly used for casting and the construction of chalets and sheds. In Western countries, wood engineering has reached another level and wood is used in ways we would not even have thought about a few years ago. Let’s take for example the first wooden skyscraper, an imposing building of 85m which was built in 2019, in Norway.

Therefore, where does all this fuss surrounding wood come from? Why so much effort and so many investments in research and development? We will clear things out in the next part.

1. Wood is a natural renewable material

This is the main reason why the developer of the biggest wooden building in the world has chosen wood, because or due to its nephews. Climate change is no longer just a topic for discussion, but a fact we are starting to experience ourselves: changes in seasons, dry summers with extreme temperatures, the desertification of Oltenia, or the lack of water for irrigation are just a few of the consequences of climate change.

The civil engineering sector has a significant percentage in the greenhouse gas emissions that contribute to climate change (40% energy consumption and 36% CO2 emissions compared to the rest of the sectors), and the manufacturing of building materials takes enormous energy quantities, the energy that comes from fossil fuels. Therefore, each building material has an associated carbon footprint.

As opposed to the rest of the building materials, wood is the only renewable material. Steel, brick, or concrete come from finite sources, while wood only needs time, water, sun, and nutrients from the soil to grow and to produce cellulose, the basic compound that gives it value as a building material. On average, 1 CBM stores 900-1000 kg of CO2. 30% of the carbon ends up in the soil, while the rest is used as “nourishment” during the growth period. The exploiting and manufacturing processes of the log in order to be turned into lumber take the energy of their own and have an associated carbon footprint, of approximately 200-300 kg of CO2. On the whole, 1 CBM of wood stores 600-700 kg of CO2.

Despite all this, we cut forests to obtain wood. Is building with wood sustainable? 2. Wood is a lightweight, resilient and durable material

It is more resilient than you would think. The wood’s mechanical resistance to compression is similar to that of concrete and bricks. For example, softwood lumber, the most used in civil engineering, can reach up to 250 kg force per cm2 at its own density of 470 kg/m3. On the other hand, normal concrete (class C20/25) has a compression strength of 250 kg force/cm2 and a density of 2200 kg/CBM and brick varies between 10-80 kg force/cm2 at a density of 1500 kg/m3.

From the structural point of view, it is important that we take into consideration the material’s supported weight compared to its own weight because the structure of the house needs to support not only exertion from inhabitants, furniture, or snow but also from its own weight. More than that, the seismic force increases with the weight of the building. A concrete or brickwork house requires a stronger foundation, which implies more concrete and steel in order to ensure the required resistance in the event of an earthquake.

On the other hand, a wooden house is 3-4 times more lightweight, it requires smaller foundations, in some unconventional situations, screwed metallic piers. Basically, under the same conditions of resilience and stability, calculated according to the design regulations, wood ensures a much better reaction to seism and because it is elastic and it takes over much better the exertions from Earth’s lateral movements. You do not believe it? Come see for yourself!

Wood is also a material with high durability in time. As proof, let’s take the churches in Maramureș that date back to the 17th-18th century. Before it is put into practice, wood needs to be dried to a humidity level of less than 18%, in order to prevent fungus, cracks, cavities, and even rotting. For instance, in contact with the concrete slab, a prefabricated wall is assembled on a hydrophobized marking sole, in order to prevent humidity transfer from concrete to wood. Furthermore, wood is treated with an insecticide- fungicide to prevent these risks.

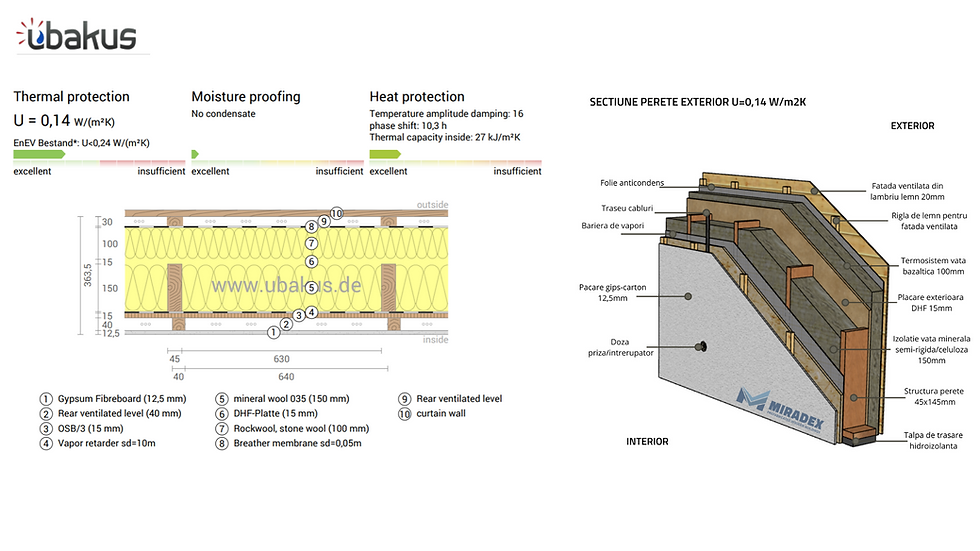

3. Wood is extremely suitable for energy-efficient houses

From the thermal point of view, wood has an advantage over the rest of the structural materials. Thermal conductivity, which shows how much heat a material conducts, is much lower than that of brick, concrete, or light steel, and it is rather included in the category of insulating material. Hence, wood is almost 4 times a better insulator than brick and 17 times than concrete.

After analyzing the table below, we realize how important thermal insulation in a building is, especially in the context of the nZEB (nearly Zero Energy Building) standard, which every residential building has to meet starting from this year. How do we build to the nZEB standard?

But wood presents another advantage, the wall's thickness. A wooden timber frame house has a very good ratio between the built area ( how much the house occupies takes of the land) and the usable area(how much space of the house we use), because in the width of the load-bearing wall, the thermal insulation ( stone wool, blown-in cellulose, wood fiber, straw).

On the other hand, a common brickwork wall of 25 cm requires a minimum of 20 cm external insulation, in order to fit into an appropriate U heat transfer coefficient, without counting the finishes.

4. Wood is highly versatile for prefabricated construction

Este un material ușor de prelucrat și manipulat, iar procesele de debitare, panotare, transport și punere în operă se pot face exclusiv mecanizat. Producția unei structuri de lemn se poate face cu utilaje specializate cum ar fi Mașinile cu Comandă Numerică (CNC) care debitează lemnul conform schemelor din proiect.

Through prefabrication, most processes are relocated to the hall, where productivity and construction quality improve, costs and risks drop According to this report, through prefabrication:

production lead time is reduced by 65%

costs drop by 45% (materials consumption, logistics, manual labor, unexpected expenses, etc)

results 75% fewer malfunctions;

Before a wooden structure is produced, the design process requires much attention to details and it is thorough because in the case of a wooden house, each millimeter and each joint detail matters. There is specialized software for wood, such as Cadwork, RoofCon TrussCon, and Pamir for calculating and modeling prefabricated wooden structures, whether industrialized roofs with MiTek connectors or timber frame structures.

Although the design is thorough and requires much time, the production lead time is the complete opposite. The production and the assembly of a timber frame structure are done just like in the case of a large-scale lego game. You take the smaller pieces ( wooden pits, insulation, plywood), you assemble the bigger elements ( prefabricated walls, roof trusses, Posi-Strut beams), you take them to the construction site and you put them together with a crane following a well-organized assembly scheme. In less than a month, you can build a semi-finished house, at least twice as fast as the brickwork option.

Moreover, there are no unforeseen costs when building with wood. The exact material quantities that will be used for the project result from the design.

5. Wood burns, but it is fireproof

We come to the most controversial aspect. It is true that wood burns, nothing to argue with. But the way it burns and the burning time count. Wood burns at a speed of 0.7 mm/min and after some time, let’s say 30 minutes, a 2cm thick layer of ash, that acts as an insulant and protects the inside from the flame, is formed. If on the outside, the burnt wood’s temperature can reach 1000°C, on the inside, that has not been reached by the flame, the temperature is about 40-50°C. The thicker, denser and damp the wood, the harder it will burn.

Of course, wood can be treated with fire to increase its resistance to fire and delay its propagation speed. We make the flame retardation of wood by immersion as a solution approved by the General Inspectorate for Emergency situations, based on the authorization to carry out flame retardation work of combustible materials. Another way of protecting a wooden building from fire is by oversizing the structural elements. It is common practice in public buildings, built from lamellar wood, which maintains structural integrity even after 60 minutes of exposure to fire. There are norms that regulate fire resistance of building materials, such as EC Delegated Regulation No 1291/2014, Act No 307/2006, and OG No 114/2000.

Although some building materials do not burn, they are still damaged in the event of a fire. Steel starts to lose its structural properties after 600°C and it breaks down under its own weight. Concrete that is exposed to fire exfoliates and after some time, it exposes the reinforcing steel that distorts from heat.

However, in the unfortunate event of a fire, the flame spreads rapidly due to the combustible materials from the inside, such as furniture varnish, curtains, and other accessories made of plastic. By the time it reaches the wooden structure, the flame has to pass first by the internal plates, such as gypsum-board, Vidiwall, non-combustible materials. Then, it is the turn of thermal insulation in the wall, such as stone wool which resists 2 hours at 1000°C.

Conclusion

Times are changing and so is the manner we build in. Internationally, efforts are made in order to reduce the impact that the way we build in has on the environment, and wood seems a very good solution. If in the last century, concrete and steel have dominated the market, it is now time for the wood to step up and to be put into practice in ways we have not thought of yet. An extraordinary building material that is provided abundantly by nature and whose true value in our country we are only beginning to discover.

Comments